In telecommunications and data transmission, fiber cleavers stand as unsung heroes, crucial in ensuring high-quality connections. These precision instruments are indispensable in splicing optical fibers, enabling the seamless flow of information across vast distances. In this blog post, we delve into the fascinating world of fiber cleavers, exploring their functionality, types, method of use, and how to choose them.

Table of Contents

ToggleWhat are Cleavage and Fiber Cleavers?

Cleavage is the process by which optical fibers are “cut” or precisely broken for termination or splicing. Like cutting a glass sheet, the fibers are cut by scoring or scratching the surface and applying stress so the glass breaks smoothly along the stress lines created by the scratches. When done properly, the fiber will be cut with a clean surface perpendicular to the length of the fiber, with no glass protruding from either end.

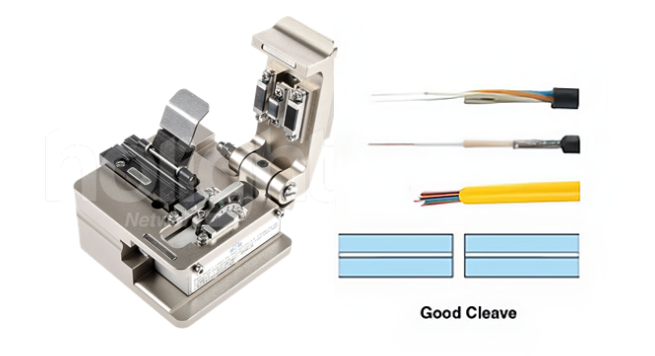

Fiber cleavers are specialized tools for cutting and preparing optical fibers for splicing. They are designed to achieve precise and clean cleaves for optimal fusion and low-loss connections. It holds the fiber under low tension, scratches the surface, and then applies greater tension until the fiber breaks. Good cutters are automatic and produce consistent results regardless of the operator. With a good fiber cleaver, clamp the fiber into it and operate its controls, and the glass fiber will cut automatically. However, some cutting machines are less automated and require the operator to manually apply force to cut the cable, making it difficult to predict and control the force.

Common Types of Fiber Cleavers

1. Scribe Cleavers

Scribe Cleavers are less expensive than precision and are the most primitive type of fiber optic cleaver. Scribe carving knives are usually shaped like ballpoint pens with a wedge-shaped diamond tip or can be cube-shaped. Scribes have a hard, sharp tip, usually made of carbide or diamond, and are used to scratch optical fibers manually. The strength is difficult to control because the breaking process is manually controlled. It is easy for the operator to break the fiber when pulled, resulting in less accurate and precise cuts. That’s why most technicians shy away from these cheap carving knives.

Pros: Precision cutting; High-quality construction for durability; Ergonomic design; Sharp and robust blades save time and effort.

Cons: Small universal range; Requires some skill and practice, not for novices; Safety concerns due to sharp blades; Sharpening the blade and keeping it clean and rust-free may require additional time and effort.

2. Field Cleavers

Field Cleavers are built to withstand rugged use and harsh outdoor conditions. The blades are high-quality hardened steel for excellent strength, sharpness, and longevity. Primarily used in multimode fiber applications, sometimes with quick connectors. With this clever, you press the blade down on the fiber to score the glass, then bend the “tail” to break the glass fiber.

Pros: Precision cleaving; Compact structure, lightweight; Easy to operate & carry; Cost savings by reducing the need for additional splicing.

Cons: Requires some skill and practice, not for novices; Fragility components require careful handling and storage; Regular maintenance and calibration to ensure precise cutting.

3. Precision Cleavers

Precision Fiber Cleavers can do more precise cutting jobs than the other two. Precision cleavers use a diamond or tungsten wheel/blade to provide a score in the fiber. Tension is then applied to the fiber to form the cleaved end face. The advantage of precision cutters is that they can produce repeatable results through thousands of cuts by simply rotating the wheel/blade accordingly. Although they are more expensive than scribe cleavers, precision cleavers can cleave multiple fibers with greater speed, efficiency, and accuracy. With the popularity of fusion splicing machines, precision cutting knives were developed to support various splicing jobs. Precision cleavers are suitable for splicing standard 125/250um and 125/900um fibers and preparing fibers for various pre-polished connectors.

Pros: Cutting and collection of waste fiber fragments can be completed in one step; Simple operation, no need to adjust the blade height; Intelligent pressure pad to prevent fiber damage; Small size, small size, and lightweight.

Cons: Higher initial cost; Calibration and adjustment complex; Fragile parts require careful handling; Maintain and replace blades regularly to ensure optimum performance.

How to Use Fiber Cleavers?

1. Scribe Cleavers Usage Procedure:

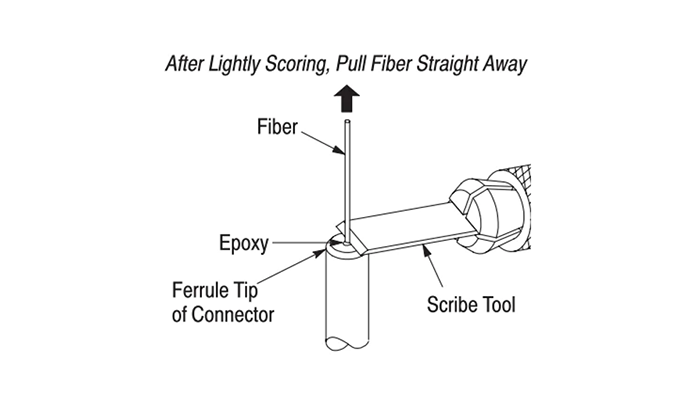

① Gently run the blade’s beveled edge across the fiber, as shown in the figure below.

② After scribing the fiber lightly, pull the fiber away from the connector directly to complete the scribing process. The fiber should be cut cleanly at the scribe point.

2. Field Cleavers Usage Procedure:

① Strip and Clean Fiber: Complete removal of the primary coating may be accomplished using a fiber stripper. Next, clean the fiber with alcohol and a lint-free wipe.

② Set Fiber: Press down on the fiber retention lever; Cut length marks line up; Keep level; Hold the buffered fiber against the end of the leaf spring and momentarily press the fiber-holding lever once more to relieve torsional stress.

③ Scoring: The blade must be gently pressed down and slowly released from the blade housing – just one stroke to the fiber.

④ Cleaving: Carefully bend the leaf spring down while continuing to hold the fiber. Bend the leaf spring just enough to separate the fiber bending can damage the spring. Release the fiber hold lever and dispose of the fiber stub. Keep it clean for good results.

3. Precision Fiber Cleavers Usage Procedure:

① Open the fuselage cover and place the stripped optical fiber on the V-groove.

② Close the stand cover.

③ Close the cover, move the slider forward, and cut the fiber.

④ Open the cover and check the cut optical fiber.

⑤ Open the bracket cover and take out the cut optical fiber.

⑥ Use a pair of tweezers to remove the fragments of the cut fiber.

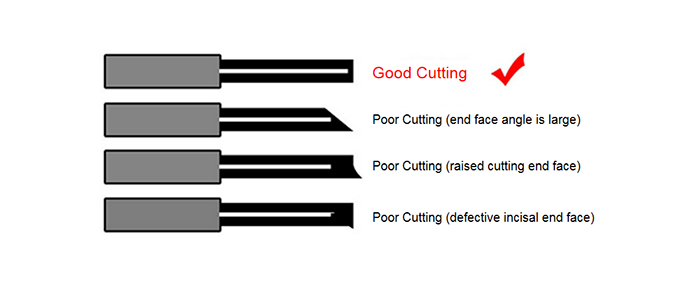

Note: Judgment of Bad Cutting End Face

If the following non-standard end faces are caused, you may need to pay attention to these aspects:

① The optical fiber is not placed straight into the guide groove;

② The blade position is too high or too low;

③ Residual garbage on the fiber holding block;

④ There are foreign objects such as dust on the blade;

⑤ There is dust or foreign matter on the optical fiber.

Tips for Choosing Fiber Cleavers

Select the fiber cleaver according to your application needs. A fiber optic cleaver designed for fusion splicing requires a low average angle of 1 degree or less, while a cleaver for mechanical connectors requires an angle of less than 3 degrees. Therefore, before cleaving fibers at a time, please determine whether you need a single fiber cleaver or a multi-fiber cleaver.

Think twice before buying a cleaver built into a fusion splicer. If you’re planning to buy a built-in cutter, you must check to see if the cutter or fusion splicer needs maintenance. Losing a valuable tool can inconvenience a technician and affect the job at hand.

Buying a meat cleaver with the latest automation features can save a lot of manpower and time. Fiber cleavers are always evolving with new and improved features such as automatic fiber waste collection, automatic scoring mechanisms and the latest in automatic blade rotation technology.