Service Support

Test items

Walsun has been adhering to the mission of “creating maximum value for customers with our most cost-effective products and services” for many years, and has established a professional laboratory testing center. Currently, it has Cisco, juniper,

Brocade and other major brands of advanced equipment, serial bit error rate tester (BERT), digital communication analyzer, light wave test system and multi-port power meter, etc. In strict accordance with the national quality

inspection standards, objective and scientific quality inspection and evaluation of products to ensure that products can work efficiently.

Compatibility testing

For all mainstream brand compatible products one-to-one real machine detection

Traffic detection

Detect optics under 1/10g network to ensure transmission quality and distance

Laser color detection

Ensure all CWDM and DWDM The channel is accurately calibrated

Storage and tag content detection

Ensure internal and external information of optical products To, accurate

Lens cleanliness detection

Check and clean high-end fiber optic lenses Eliminate light pollution

Management indicators

Supplier manageme

Complete system review and risk control when suppliers are imported; Regular on-site inspection and coaching of suppliers; Fair and reasonable trading principles.

Incoming inspection and warehouse management

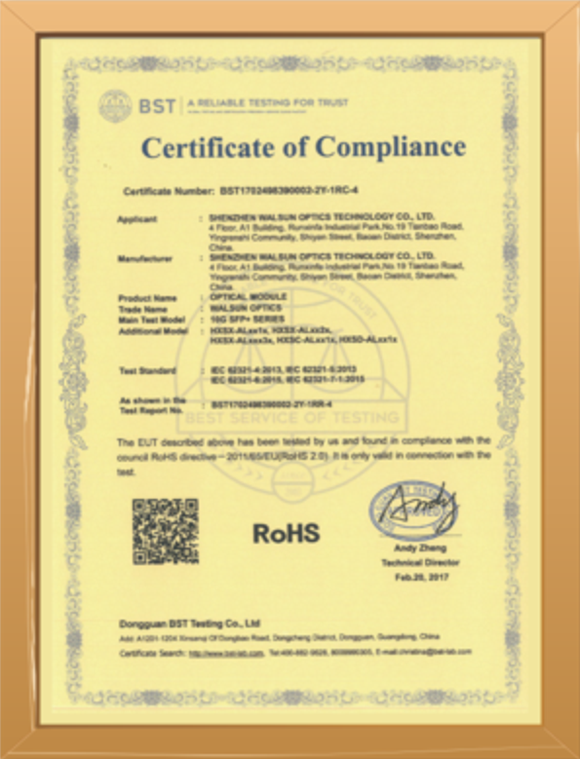

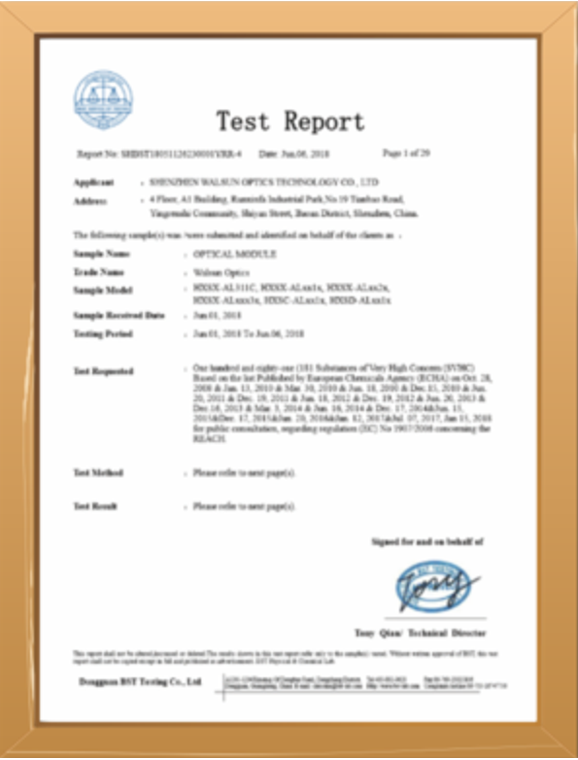

Sampling inspection of incoming materials; Implementation of RoHs environmental monitoring; Standard warehouse classification and environmental control; Safe inventory management principles.

Production process quality control

Timely handling of defective products; using statistical methods to control the product defect rate; analyzing the first batch of production and quality to identify and assess quality trends; conducting irregular inspections of the production line to achieve continuous improvement and maintain quality.

Shipping quality control

Sampling and inspecting finished products to ensure product quality meets specifications; reviewing product quality according to the production flowchart; preserving data for all produced products.

Product reliability inspection

Conducting reliability tests according to different product quality standards and customer requirements. The inspection process includes: testing insertion loss, testing return loss, ferrule end face inspection, interchangeability, vibration, tensile strength, and high-low temperature cycling; providing standardized internal test reports.

Environment and System

Maintaining a clean workshop environment and scientific production management: thorough 6S safety and hygiene management; implementation of visual management/goal management; making all problems visible and addressing them quickly; maintaining a stable, high-quality workforce; turnover rate below 5%.

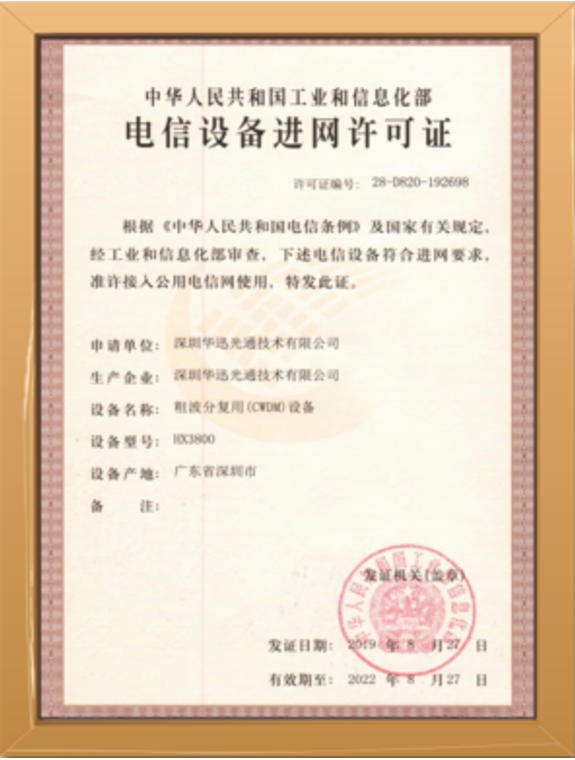

Quality Certification