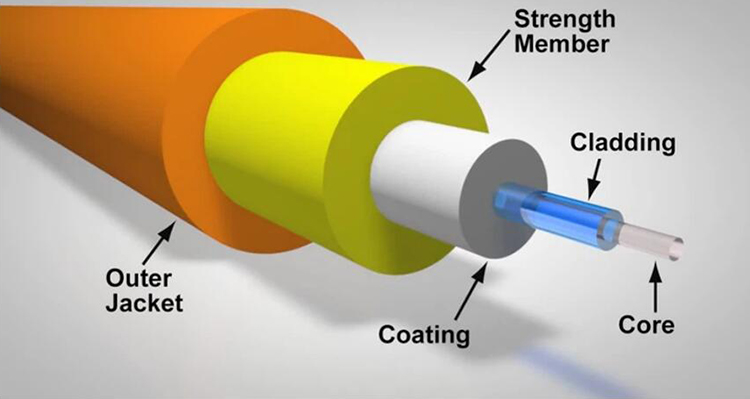

In this digital age, our lives are increasingly dependent on fast and reliable internet connections. The backbone of these connections lies in the vast network of fiber optic cables that span across continents, cities, and even homes. However, achieving optimal performance from fiber optic cables requires precise installation and maintenance, which is where fiber polish machines come into play. These cutting-edge devices play a crucial role in ensuring the efficiency and longevity of fiber optic connections. This article will delve into the intricacies of fiber polish machines, highlighting their functions, importance, and the impact they are making on the connectivity landscape.

Table of Contents

ToggleUnderstanding Fiber Polish Machines:

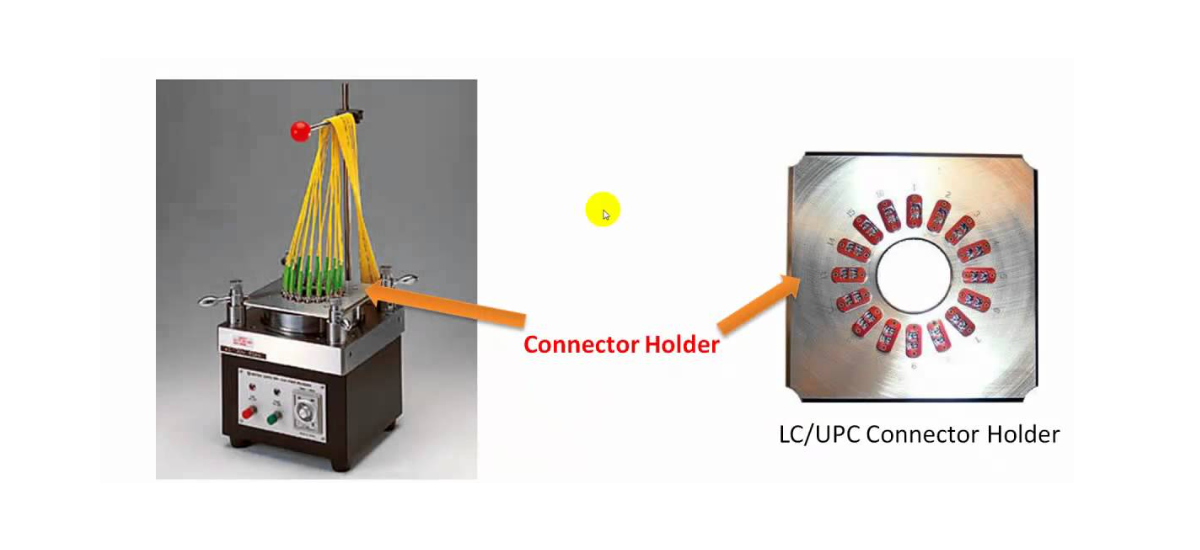

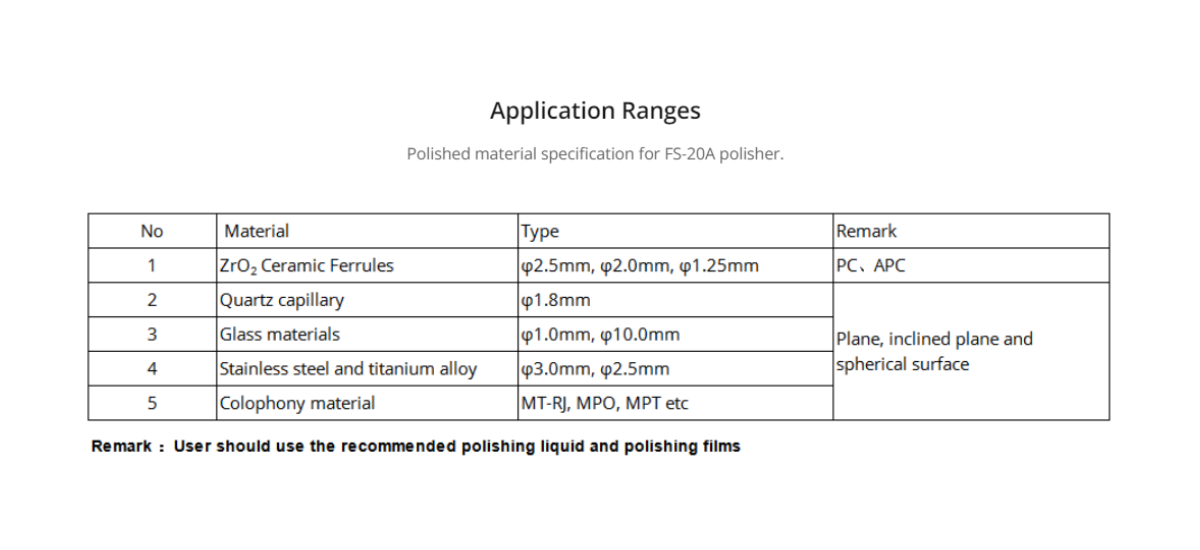

Fiber polish machines are specifically designed to prepare and polish fiber optic connectors, an essential step in the installation process. These machines utilize a combination of mechanical force and abrasive material to remove any imperfections on the connector end face, ensuring optimal transmission of light signals. They operate under controlled conditions to achieve the highest precision, comprising various components like polishing plates, pressure-control systems, and automated polishing programs.

Importance of Fiber Polishing:

Signal Loss and Return Loss:

Explanation of signal loss and return loss, the role of connector polishing in minimizing losses.

Reflections and resulting signal degradation if connectors are not properly polished.

Performance Enhancement:

Improved transmission performances with polished connectors, such as signal integrity and reduced bit error rates.

Role of fiber polish machines in achieving consistent and reliable communication.

A well-polished fiber optic connector offers several benefits. Firstly, it minimizes signal loss, optimizing connection efficiency and maximizing data transfer speeds. Secondly, the uniform polishing creates a robust and reliable connection, reducing the risk of interruptions and ensuring consistent performance. Lastly, fiber polish machines help extend the lifespan of connectors by eliminating contaminants, preventing scratching or damage, and enhancing overall durability.

Types of Fiber Polish Machines:

Fiber polish machines come in different forms, each tailored to specific polishing needs. Two commonly used types include:

Automatic Polish Machines:

Automatic polish machines are highly advanced devices designed for mass polishing production. These machines can simultaneously process multiple connectors, dramatically reducing polishing time and increasing productivity. Equipped with robotic arms, they ensure uniform pressure distribution, consistent polishing profiles, and ultra-precise results. Automated polish machines are ideal for large-scale fiber optic projects that demand high throughput and efficiency.

Handheld/Portable Polish Machines:

Handheld or portable polish machines offer greater mobility and flexibility, making them suitable for field applications. These compact machines are often battery-powered and allow network technicians to polish fiber optic connectors on-site. With adjustable settings and interchangeable polishing heads, handheld polish machines cater to various connector types and polishing requirements. Their versatility makes them indispensable for troubleshooting, repairs, and maintenance tasks.

Advancements in Fiber Polish Technology:

Over the years, fiber polish machines have witnessed significant advancements, driven by continuous research, innovation, and growing demands within the telecommunications industry. Some notable technological developments include:

Computer-Aided Polishing (CAP):

Computer-Aided Polishing (CAP) has revolutionized the precision and efficiency of fiber polishing. CAP involves the use of advanced algorithms and real-time data analysis during the polishing process. By constantly monitoring polishing parameters such as pressure, rotation speed, and polishing time, CAP algorithms optimize polishing profiles and minimize human error, resulting in higher quality and consistent connector performance.

Enhanced Polishing Plate Materials:

The polishing plates within fiber polish machines have undergone improvements to enhance the polishing process. Traditionally, polishing plates were made of ceramic materials such as zirconia, but recent advancements have introduced synthetic materials like photonic crystals. These materials offer better durability, abrasive effectiveness, and improved control over the polishing process.

Real-time Inspection:

Integrated inspection systems have become common in modern fiber polish machines. These systems use advanced imaging techniques to capture and analyze the connector end face during polishing. By assessing parameters like surface roughness, geometry, and fiber core alignment, real-time inspection allows immediate feedback and adjustment, ensuring optimal polishing results.

Advantages of Fiber Polish Machines:

Precision and Consistency:

Features and mechanisms designed for consistent polishing results.

Automated processes ensure precise and repeatable performance.

Time and Cost Efficiency:

Impact of manual polishing on labor costs, time consumption, and potential errors.

How fiber polish machines streamline and expedite the polishing process, reducing operational costs.

Enhanced Longevity:

The connection durability and lifespan achieved through proper polishing.

Significance of fiber polish machines in maximizing connector lifespan.

Applications of Fiber Polish Machines:

Fiber polish machines are vital in various industries and sectors, including telecommunications, data centers, healthcare, and research laboratories. Here are a few notable applications:

Telecommunications:

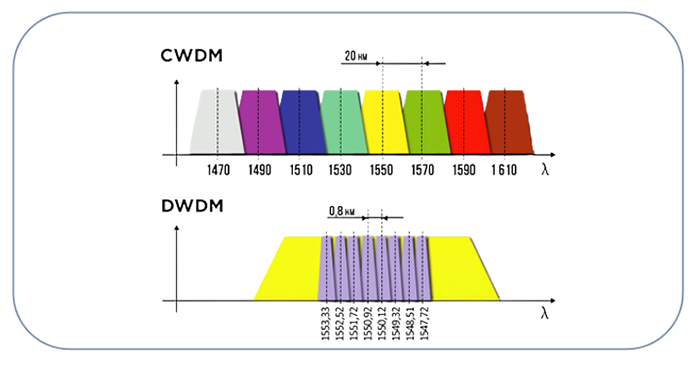

The telecommunications industry widely employs fiber polish machines to ensure reliable and high-performance connections. From large-scale network infrastructure projects to individual fiber optic repairs, fiber polish machines play a crucial role in maintaining robust and efficient connectivity.

Data Centers:

Data centers rely on fiber optic connections to handle enormous volumes of data. Fiber polish machines are used to install and maintain connectors within these centers, ensuring uninterrupted data transfer and minimizing latency.

Healthcare and Biomedical Research:

Fiber optic technology is commonly used in medical imaging, surgical procedures, and diagnostic equipment. Fiber polish machines are vital for maintaining high-quality connections in medical settings, improving the accuracy and reliability of patient monitoring systems, robotic surgeries, and image-guided interventions.

Laboratory and Research Settings:

Research laboratories heavily rely on fiber optic equipment for various experiments and testing procedures. Fiber polish machines enable precise connections required for advanced research instruments such as spectroscopy devices, scientific imaging systems, and optical sensors.

Latest Developments and Future Trends:

- Automation and Robotics:

Evolution of fiber polish machines towards automated systems.

Integration of robotics and AI for improved speed and accuracy.

- Advanced Fiber Cable Technologies:

Introduction of new connector types with improved polish requirements.

Fiber polish machines adapting to cater to these emerging technologies.

Conclusion:

Fiber polish machines have become indispensable tools in achieving high-performance and reliable fiber optic connections. Their ability to produce finely polished connectors ensures minimal signal loss, enhanced longevity, and consistent performance. As technological advancements continue to shape the telecommunications industry, fiber polish machines will play a crucial role in maintaining and improving connectivity across the globe. If you want to know more about this, please feel free to contact Walsun. The future holds even greater possibilities for these remarkable machines, as research and development continue to unlock new capabilities, further revolutionizing the connectivity landscape!